|

|

| Figure 1. Bobtailing is the

visible piece of the deadhead problem |

This component of the MeTrIS project addresses the problem of

“deadhead”

travel by trucks in

port cities, with particular reference to Los Angeles.

For each trip that hauls goods, there are on average 1.6 deadhead trips that reposition empty containers, chassis and tractors. Consider the steps:

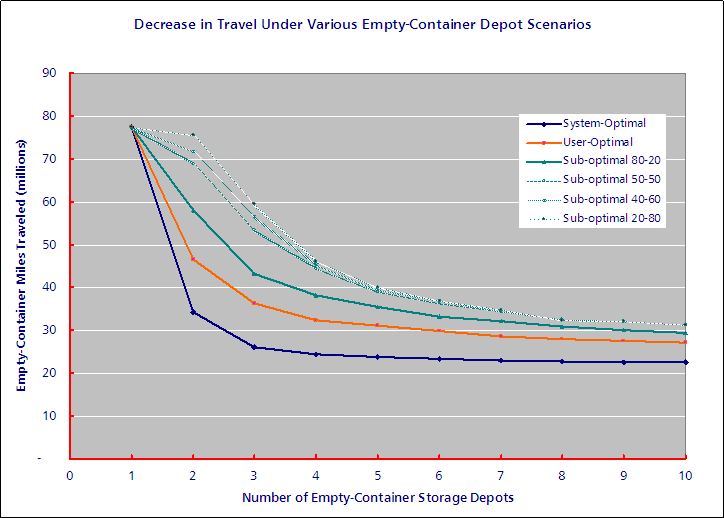

Deadhead trips can be greatly reduced by establishing empty-container storage depots at strategic, optimized locations. The curves in Figure 2 show the reductions that can be realized under various scenarios.

The system-optimal model dictates to truckers where an empty container is to be taken, to optimize the overall system. In the user-optimal model, truckers serve their own interests by taking empties to the nearest depot. The sub-optimal models examine likely working scenarios where say only 80% of truckers are able to use the first-choice facility, while the remaining 20% use other facilities for various reasons. The curves in Figure 2 similarly document 50-50, 40-60 and 20-80 use of the first-choice facility.

With more depots, there is clearly a reduction in distance traveled,

but it is the first 3-4 depots that have the greatest impact and are

most worth the investment. With sub-optimal use, more depots are

required.

The net benefit of these empty-container management strategies is an

enormous reduction in empty movement (Figure 2), translating to

approximately 25% reduction in port area VMT, and a reduction

of 4,500 port entries and 50 tons of CO2

emissions per day.

|

| Figure 2. A system of empty-container depots

can result in dramatic decreases in travel |